May. 15, 2023

Minerals & Metallurgy

Introduction :

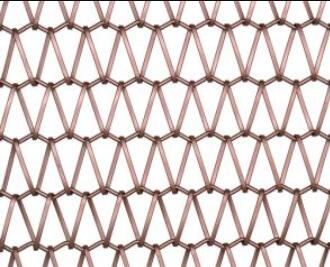

Spiral woven mesh is a unique and versatile material with a wide range of applications. It offers a myriad of benefits, making it an excellent choice for various industries. In this article, we will explore the features, applications, and advantages of spiral woven mesh.

Overview of Spiral Woven Mesh :

Spiral woven mesh is a type of wire mesh made by interlocking spirals of metal wire. This weaving technique creates a strong and flexible mesh structure that is resistant to corrosion, heat, and pressure. The mesh is typically composed of stainless steel, making it durable and long-lasting. It is available in various diameters, mesh sizes, and configurations, allowing for customization to meet specific requirements.

Applications of Spiral Woven Mesh:

Spiral woven mesh finds applications across a diverse range of industries. It is commonly used in filtration systems, where it effectively separates solids from liquids or gases. The mesh's fine yet sturdy construction enables precise filtration and ensures high flow rates. Additionally, spiral woven mesh is employed in architectural applications for decorative purposes, creating unique patterns and visual effects. It is also used in conveyor belts, machinery guards, insulation, animal enclosures, and various industrial processes where strength, flexibility, and durability are crucial.

Suggested reading:

Benefits of Spiral Woven Mesh:

The inherent qualities of Spiral Architectural Mesh contribute to its numerous advantages. The interlocking spiral structure provides exceptional strength and resistance to mechanical stress. The material's high-temperature tolerance makes it suitable for applications involving heat, such as ovens, furnaces, and industrial drying equipment. Furthermore, spiral woven mesh offers excellent corrosion resistance, ensuring longevity in harsh environments. Its open structure allows for efficient fluid flow and prevents clogging, making it ideal for filtration applications. Moreover, the customization options in terms of wire diameter, mesh size, and configurations enable tailored solutions for specific needs.

Conclusion :

Spiral woven mesh is a versatile material that finds applications across various industries due to its durability, flexibility, and corrosion resistance. Its unique interlocking spiral structure provides strength and longevity, making it suitable for demanding environments. Whether used for filtration, architecture, or industrial processes, spiral woven mesh offers reliable performance and tailored solutions.

Previous: Decoration Profiles: Enhancing Spaces with Style and Functionality

Next: Dead Burned Magnesia: Properties, Uses, and Production

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )